The history

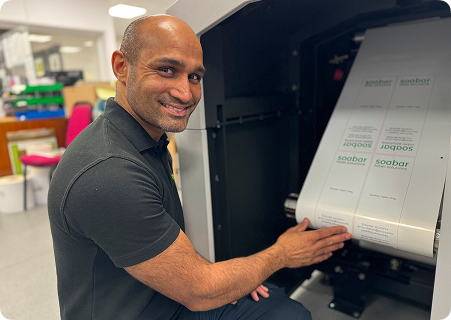

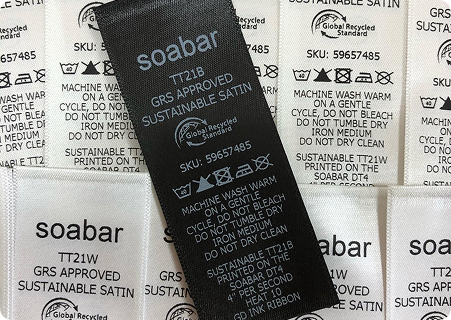

Soabar has been supplying labels and associated machinery at our Whetstone, Leicester site since the 1970s, but our origins date back over 100 years, serving the apparel markets in the United States.

Originally established as one of various worldwide operations concentrating on textile market labelling solutions, Soabar UK quickly became the market leader in this field. Over time, we identified labelling solutions for many different industries and are now recognized as one of the leading label solution suppliers for a wide variety of sectors including:

Our Solutions

Our range of label printing systems is constantly updated to meet the challenges of today’s rapidly changing marketplace. We offer comprehensive support at every stage:

-

Our in-house design team produces quality artwork for your labels

-

Our technical support department offers assistance with thermal printers and label software

-

Our production department creates high-quality digital and flexographic labels

The Soabar Difference

At Soabar, we are renowned for our expertise within the label industry. We help you choose the right printer, software, and labels to provide a complete solution that works for your business saving you both time and money. With our on-site installation, training, and warranty as standard, you can be confident you’re in safe hands.

The Soabar Journey

2025

2024

2023

2021

2019

2016

2008

2005

2004

1989

1985

1980

1978

1970

1950

1914

2025

At the start of the year we were awarded a Bronze Medal from EcoVadis, further recognising our company-wide commitment to sustainability and corporate social responsibility. We are currently in the top 35% of print companies when it comes to our environmental and social governance. Mid-way through the year Soabar invested in Peel and Reveal technology, allowing our customers to order multi-layered labels for their products.

2024

Work began and was completed on the building extension at the Whetstone site, adding roughly 4,000 square feet to our factory and production space. Alongside this expansion, changes were also made to our workflow processes as company-wide, we adopted Cloud Flow. Processes were optimised and the volume of work that we could take on increased significantly, thanks to both physical and technological change. In November, Soabar achievedaFSC® (Forest Stewardship Council®) Chain of Custody Certification (C208984), emphasising our dedication to promoting sustainability and responsible sourcing practices.

2023

Upgrades were made to our Konica Minolta and ABG Digiseries presses, as simultaneously we invested in Bobst Mouvent digital inkjet technology. This allowed us to run orders at speeds of up to 100m per minute, significantly increasing output and the quality of print we were able to offer our customers.

2021

Soabar’s internal computer system was upgraded to Label Traxx, an all-encompassing job management system for our label printers. Order processing and production speeds increased significantly, and printing results were more precise and reliable.

2019

Upgrades were made to the Konica Minolta machines just before the Covid-19 pandemic swept across the globe. The reliance of these presses allowed Soabar to carry on printing pharmaceutical labels throughout the pandemic, for use in medical facilities and hospitals up and down the country.

2016

Digital label printing arrived on the scene and Soabar had to move fast to adopt this new technology. We became the second company in the country to invest in Konica Minolta’s Bizhub as part of their CF71 Digital Press, and the popular ABG Digilite 3 Series became part of the factory furniture. This allowed us to take on short run work that could be printed at high speeds and meant that we could offer our customers a fully finished printed label that could go straight onto their products.

2008

Phil Achurch became Managing Director of the company and took it from strength to strength. Large investment was made in our Flexographic Printing Presses and allowed the Soabar to remain competitive in the industry, as technology continuously advanced.

2005

Soabar’s printing services were drawn upon following the tragedy of the Buncefield fire which occurred on 11th December 2005. This was our first large-volume work for company Autoglym, and solidified Soabar as being able to offer more than label embellishment. We could print more information onto labels and provide customers with the ‘whole package’ for their labelling needs.

2004

Thanks to a timely investment in the Omega Turret machines back in 1999, Soabar began to reach national markets and become a common-place name in the print industry. We won business with Republic Clothing which demanded some printing to be outsourced to Dalian in China, where a large chunk of the company’s clothing production was based at the time.

1989

More investment was made in an 8 colour, reverse print Ko-Pack printer that expanded our market reach further. Businesses in the apparel and textile industries remained our key customers, but slowly we could take on new work in different sectors such as food and beverage, thanks to our enhanced print capabilities.

1985

Soabar diversified business as the demand for labels from the apparel industry began to decline. Our engineers curated Soabar’s own range of desktop label printers, and equipment began being sent to customers in the city. The business invested in two the state-of-the-art Ko-Pack machines which are letter press printers that remain operational to this day. They offer quick set-up times, print crisp, high quality labels and for the first time, we could print self-adhesive labels for our customers.

1980

The successful print company, Sessions of York, took over the business and Soabar separated from Avery. Card and satin labels were the main goods sold by Soabar, retaining the company’s strong links with the textile and garment industries.

1978

Soabar relocated just 13 miles down the road to Whetstone, a village in South Leicestershire, where it remains today. Just 7 people worked in the new factory space, and the company’s associations with Avery Dennison remained strong.

1970

The port city of Plymouth became the first place to welcome Soabar to the UK print market. Shortly after this in 1973, the business was relocated to Ibstock in Leicestershire, largely to serve to booming hosiery manufacturers in the city.

1950

Soabar was taken over by the well-known global print company, Avery Dennison. Business began to grow at a considerable speed in the textile and garment industry.

1914

Soabar was founded in Philadelphia, USA. Bars of fabric were sewn into the uniforms of serving soldiers to ensure colour consistency across clothing garments. From this innovation, the name Soabar (‘sew a bar’ of fabric) was born.

Frequently Asked Questions

Browse common questions about our labels, printers, software, and services. Can’t find what you need? Just ask us.

01

What is the lead time for an order?

We have a lead time of 5-7 working days for a digitally printed label order, 7-10 days for any blank labels, and 10-14 days for label orders printed on one of our flexo machines. If you’re unsure which category your order will fall under, then contact our team for a prompt answer.

02

What will the delivery cost be?

Our carrier charge is £10.16 for deliveries weighing up to 20kg. Once shipped, your order will be with you by the next working day!

03

Do you have a minimum order quantity?

No, we don’t have a minimum order quantity. All orders are priced up in accordance to your specifications, and quantity options will be given to you by one of our friendly team.

04

Can I choose sustainable materials for my labels?

Yes you can! We have various FSC accredited materials that your labels can be printed onto, and compostable options also.

05

What types of labels do you print?

We print self-adhesive labels, both printed and non-printed (blanks), card and textile labels. We also print barcode labels, tamper-proof labels and window stickers. Speak to our team if you have any specific questions, as we’ll always try our best to fulfil your requirements.

06

What format does artwork for my label order need to be in?

We kindly ask for all artwork to be sent as individual files in a PDF Print format. All fonts should be outlined, and a 2mm bleed applied to all label sides. Colours must be supplied in either CMYK or Pantone, and images should be a minimum of 300dpi resolution.

07

I’m not based in the UK, can I still order labels/products from you?

Yes of course! We ship overseas for an extra charge, and always provide the same excellent level of customer service with every order. No matter where you are in the world!

08

Why are all label prices on your website an approximate?

There are a lot of variables to consider when placing a label order. The specific material, finish and whether a label is single or double sided are all factors at play, as is the shape of the label. We do our best to supply as accurate an estimate as possible on our website, however this price might go up or down slightly depending on these factors.

Stay Informed with Soabar

What’s In: Label Design Trends 2026

At Soabar, we’ve had a front row seat for the evolution of label design trends for over 45 years. We’ve...

Label Finishing Operator

Grade: Operative Reports to: Production Manager Full time position 37.5 hours per week Objective: To assist in the smooth, productive...

Soabar Achieves EcoVadis Bronze Medal

How To Print Your Own Labels. In today’s competitive business environment, printing your own labels can make a

Let’s Talk Labels

Need the perfect label, printer, or software for your business? Our team is ready to help you choose the right solution, answer your questions, and provide a personalised quote. Let’s make labelling easy.