GHS Labelling Requirements: A Guide for UK Businesses

Posted on 05/06/2018 in Company News, by Jon

Introduction to GHS Labelling

Chemical safety is paramount in workplace environments, and the Globally Harmonised System (GHS) provides a critical framework for communicating chemical hazards effectively. Developed by the United Nations, GHS Labelling Requirements create a standardized approach to chemical labeling that transcends international boundaries, ensuring clear and consistent communication of potential risks.

The Evolution of Chemical Labelling

Before the Globally Harmonised System (GHS), chemical labeling was a chaotic landscape. Different countries used varying symbols, inconsistent language, and often confusing terminology. This lack of standardization created significant risks for workers handling hazardous materials.

The Global Challenge

Imagine a scenario where a chemical worker in Manchester might interpret a label differently from a colleague in Manchester, UK, and another in Manchester, USA. The potential for misunderstandings was enormous, and the consequences could be life-threatening.

Legal Context in the UK

In the United Kingdom, GHS labeling requirements are implemented through the Classification, Labelling and Packaging (CLP) Regulation, which aligns with European and international standards. Businesses must comply with these regulations to ensure workplace safety and legal compliance.

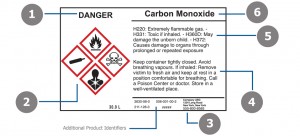

Essential Components of a GHS Label

1. Signal Word

The signal word indicates the severity of the chemical hazard:

- Danger: Signifies more severe hazards

- Warning: Indicates less severe hazards

💡 UK Insight: UK regulators take signal words very seriously, using them as a quick visual indicator of potential risks in workplace settings.

2. Hazard Pictograms

Nine standardized pictograms communicate specific types of hazards:

Chemical/Physical Risks

- 🔥 Flame: Indicates flammable substances

- 💥 Exploding Bomb: Signifies explosive materials

- Gas Cylinder: Represents pressurized gases

Health Risks

- 💀 Skull and Crossbones: Toxic substances

- 😷 Health Hazard: Indicates chronic health risks

- Corrosion: Represents corrosive materials

Environmental Risks

- 🌳 Environment: Signifies environmental hazards

3. Manufacturer Information

Must include:

- Company name

- Full address

- Contact telephone number

🇬🇧 UK Requirement: Ensure contact information is a UK-based address and phone number for local regulatory compliance.

4. Precautionary Statements

Detailed guidance on:

- Hazard prevention

- Safe handling procedures

- Emergency response protocols

- Storage recommendations

5. Hazard Statements

Specific descriptions of chemical hazards, identified by unique H-codes. Examples:

- H220: Extremely flammable gas

- H300: Fatal if swallowed

- H315: Causes skin irritation

6. Product Identifiers

- Clear chemical or product name

- Additional identifying information if necessary

Practical Considerations for UK Businesses

Label Design Tips

- Use clear, legible fonts

- Ensure high contrast between text and background

- Consider label durability in various environmental conditions

Printing Solutions

- Invest in specialized label printing systems

- Use durable materials resistant to workplace conditions

- Consider on-demand printing for flexibility

Common Mistakes to Avoid

- Incomplete hazard information

- Illegible or faded labels

- Outdated chemical classification

- Non-compliance with current UK regulations

Risk Assessment and Management

Comprehensive Approach

Effective chemical management goes beyond labeling:

- Regular risk assessments

- Continuous staff training

- Implementing hierarchy of control measures

Training Recommendations

-

- Annual comprehensive safety training

- Specific chemical handling workshops

- Emergency response simulation exercises

Technological Innovations

Modern label design software like NiceLabel allows for:

- Customizable templates

- Variable data integration

- Easy compliance updates

Emerging Trends

Sustainability in Chemical Management

- Increased focus on environmentally friendly alternatives

- Transparency in chemical composition

- Lifecycle assessment of chemical products

Technological Innovations

- AI-powered risk assessment tools

- Blockchain for chemical traceability

- Advanced materials for more durable, informative labels

Conclusion

Effective GHS labeling is more than a regulatory requirement—it’s a critical component of workplace safety. By understanding and implementing these guidelines, UK businesses can protect their employees and maintain regulatory compliance.

Next Steps:

- Audit current chemical labeling practices

- Invest in professional labeling solutions

- Conduct comprehensive staff training

Contact Information

For specialized GHS labeling solutions, consult with local safety compliance experts who understand UK-specific requirements.

When you’re ready to print your GHS labels, then contact our knowledgeable team at Soabar who will print your labels to the highest quality at a competitive price.