How We Print It: Food & Packaging Labels

Posted on 24/04/2025 in Company News, by Emma Achurch

From Print To The Vending Machine: Milkshake Labels

At Soabar we print a wide variety of labels for a range of different industries, that are then shipped both nationally and internationally. This is a snapshot into how we print it!

Every day thousands of meters worth of labels come off our presses, to then likely serve as a product’s single most important marketing tool that will drive a customer purchase. But not many people know exactly how a product’s label has been printed, and the different steps that go into making each label order perfect.

Today we zoom in on one of our wonderful local customers, Fulmore Farm Dairy, and their most recent order with us.

Located just 2 miles away from our offices and factory in Whetstone, Leicestershire, they have a vending machine on site that stocks a range of milkshake flavours and a milk and syrup dispenser that allows you to make up your own!

Follow the label’s life from artwork to bottle to gain an insight into how we print it!

The Production Process

For this particular order (1,000 vanilla milkshake labels) we’ll be printing onto a gloss white polypropylene (PP), a durable material perfect for products that might encounter moisture or refrigeration. This short-run job follows a carefully orchestrated workflow, that has been finessed to ensure maximum efficiency and accuracy.

For this particular order (1,000 vanilla milkshake labels) we’ll be printing onto a gloss white polypropylene (PP), a durable material perfect for products that might encounter moisture or refrigeration. This short-run job follows a carefully orchestrated workflow, that has been finessed to ensure maximum efficiency and accuracy.

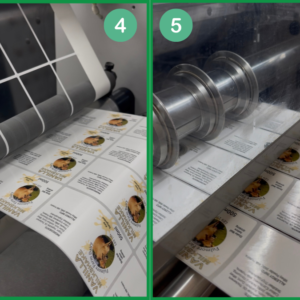

Preparation and Printing

The process starts with checking the ticket details and ensuring that the printing department have the correct material and size specifications. We locate the appropriate artwork file on our system and transfer it to the printer (1). The printer settings are calibrated for optimal print quality, and we always have another team member verify everything before going ahead and printing the label order. This is a crucial step in our quality control process.

Once sign-off is received, printing of the label order begins (2). We select the correct artwork, style, speed, and quantity settings, then monitor the printing process carefully to ensure the output meets our standards.

After printing, we unload the material and mark the roll with the ticket number for identification. The printed rolls are then placed on a pallet ready for the finishing department, and we update our records in the LabelTraxx system.

The Finishing Process

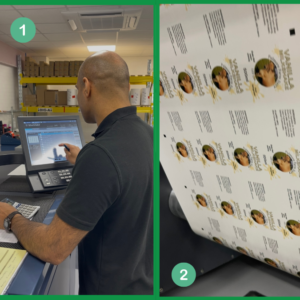

The printed rolls move to the Digicon Series 3 finishing machine, where several processes happen in a slick sequence:

- First, a gloss varnish is applied to protect the labels from environmental factors, scuffing, and ink rub-off (3).

- Following this, the labels move through the die station where they’re cut into their distinctive shape, in this case a rectangle.

- The excess material is then stripped away, leaving only the shaped labels (4).

- Finally, auto slitters divide the material into four different webs (or strips), creating four separate rolls of the finished product (5).

Packaging and Delivery

Each finished roll receives an end roll label (6) containing information such as the size, material, quantity, date and ticket number. This is stuck on to each roll, which will then mean that the rolls can be boxed up ready for shipping (7).

This is stuck on to each roll, which will then mean that the rolls can be boxed up ready for shipping (7).

Once placed into the box we then print a further box label, which details the customer information, the weight, quantity of labels and the date it was packed. We also pop on one of the spare labels from the customer’s rolls we’ve just printed, to make it even easier to identify (8).

For shipping, we typically use APC courier for next-day delivery. This is the quickest way to get it to our customers that are further away. However in this instance, Fulmore Farms is only a 6 minute drive away, so the farmers will likely come and pick it up themselves!

To the Vending Machine!

A few days later, we took a visit to see the labels that we printed stuck onto the milkshake bottles inside the vending machine.

We print all of the labels for each of the milkshake bottles in the vending machine, but these ones we just printed were specifically for the classic vanilla flavour.

To work the vending machine all you have to do is key in the corresponding code (9), tap your card and the milkshake will drop down for you to collect (10). They’re served chilled and cost just £1.75 for the smaller size. They have so many different flavours to choose from (11)!

We love printing labels for local businesses like Fulmore Farm Dairy, and are so proud when we spot our labels when visiting stores. All of our labels are made to the highest quality and ensure that products are eye-catching, unique and compliant with industry standards.

To find out more or to enquire about a label order of your own, then get in touch with us today!