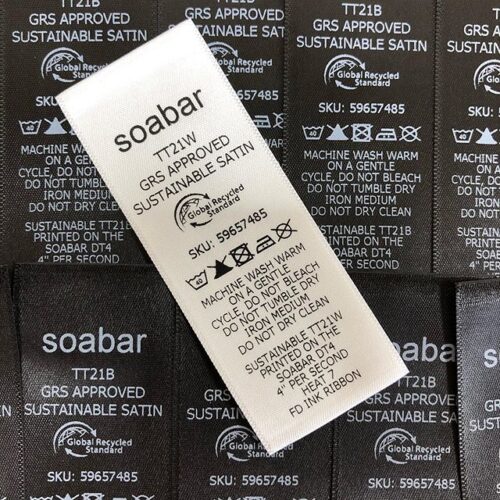

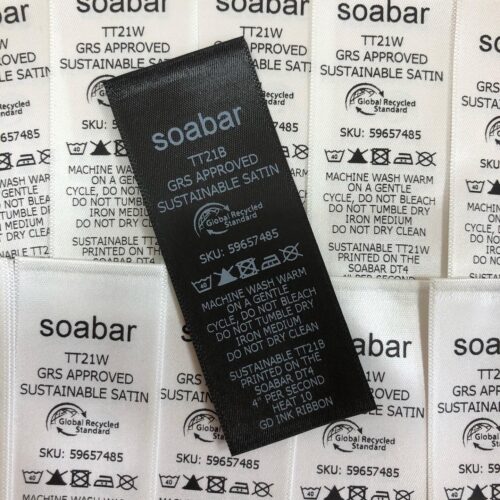

Sustainable Ribbon

The Process

Our recycled yarn is made from 100% post consumer waste PET bottles. Our control begins from the collection of the bottle through to the finished woven ribbon. This transparent process, from bottle to ribbon, is audited and certified by the Global Recycled Standard (GRS).

Bottle collection

There are numerous collection points within China creating the opportunity for local people to earn an income and improve their local environment.

Sorting and bailing

Once the bottles reach the collection point they are sorted into different grades. They are then crushed into bails for ease of storage and transportation to our yarn factory.

Washing

The bails are separated to allow the bottles to be washed removing as much dirt, labelling and contaminants as possible.

Flaking

The bottles are ground into flake and are put through a second wash process at which stage any leftover residue and bottle tops are separated, leaving a cleansed PET flake.

Extruding

The flake is molten into liquid form and extruded at high pressure into yarn. The yarn is now ready to be woven into our luxurious and sustainable ribbon.

Our goal is to recycle 90% of the water in our manufacturing process. On average, 20% of the energy used in the manufacturing process of our yarn is solar energy.

Our process reduces the impact on the environment

Eliminating the creation of virgin yarn. No oil is extracted from the ground when making our recycled products.

Reduced CO2. We use less energy and produce less greenhouse gases by producing 100% recycled PET as opposed to virgin PET.

Reduced landfill. It is our aim to prevent 56 million bottles from entering landfill and our seas each year.

If you want to find out more about our sustainable ribbon, please get in touch

Gallery